Ever wondered how you can keep up with the fast-paced demands of your milk tea business with limited staff? The WantJoin Cup Sealing Machine might just be the ally you need. This device prides itself on functionality, boasting swift cup sealing speeds and ease of operation to ensure a smoother workflow in your establishment. Let’s get to know this product a bit better.

This image is property of Amazon.com.

WantJoin Cup Sealing Machine: A Game Changer

Imagine the relief of a machine seamlessly taking over a repetitive task like cup sealing. That’s what the WantJoin Cup Sealing Machine offers. It automates the entire cup sealing process, liberating your team to focus on other customer-oriented services. It rolls the film over the cup, seals it tightly, and ejects it, all at the push of a few buttons.

How It Works

The design cleverly integrates automation with efficiency. After placing the cup, the machine kicks into action, streamlining the whole sealing job. It comes equipped with a digital control LCD panel, making it straightforward for anyone to operate. Whether it’s a bubble milk tea or coffee you’re serving, this machine promises consistency in sealing every single time.

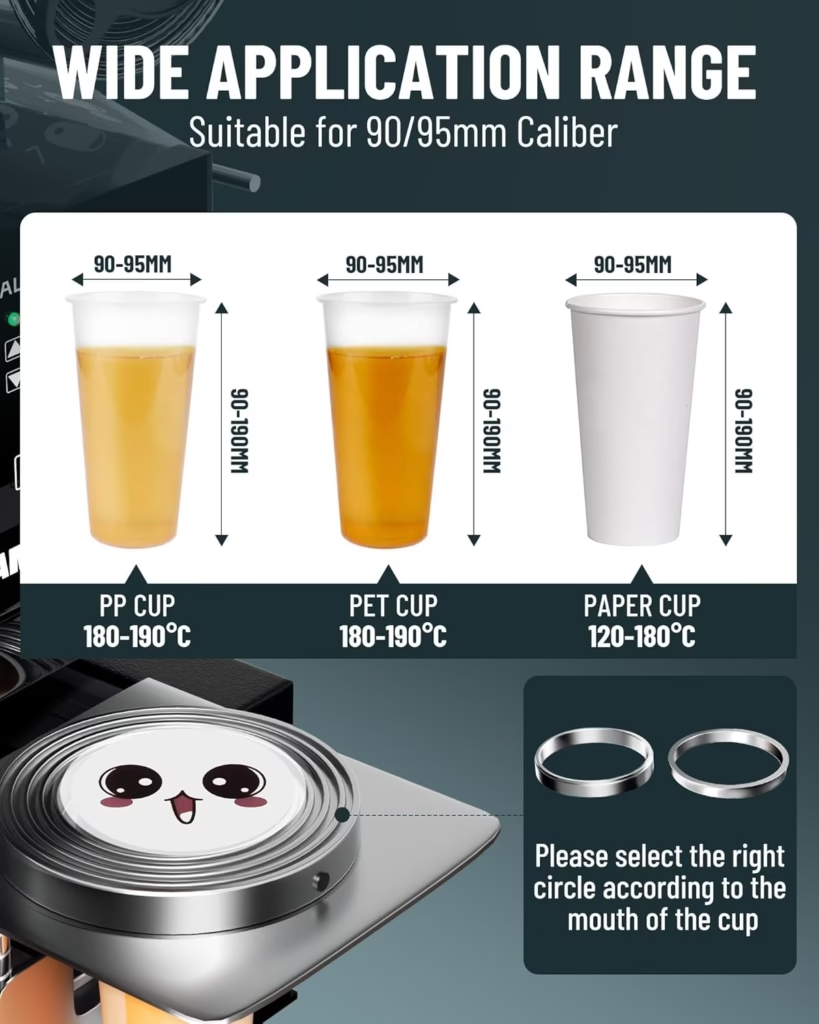

Compatibility with Different Cup Sizes

A unique selling point here is the machine’s versatility with cup sizes and materials. Whether you’re using paper or plastic, the device accommodates both effortlessly. It’s designed to seal cups with 90mm or 95mm calibers, and variations in height from 9cm to 19cm are not an issue. Imagine, no more hassles with mismatched sizes or materials.

Material Versatility

Not just limited to variations in size, the WantJoin Cup Sealing Machine also caters to a spectrum of materials. Be it PE, PP, or PC plastic cups, this machine seals them all with a snug fit. Its flexibility reinforces its value, especially in a dynamic environment where product offerings may change from week to week.

| Component | Description |

|---|---|

| Cup Size | 90mm or 95mm cups |

| Cup Height | 9cm to 19cm |

| Material Compatibility | PE, PP, PC |

This image is property of Amazon.com.

Why Manual Handling is an Advantage

Despite being fully automatic, there are times the human touch becomes necessary. If the first seal isn’t to satisfaction, you can manually adjust or patch it through a straightforward process. This feature ensures no compromised drinks for your customers—especially useful during peak hours when rushing is unavoidable.

Wet Mouth? No Problem

One challenge with sealing is handling wet mouth cups. This machine tackles that efficiently, catering to specific customer requests without holding up the line. The manual speed settings provide you with more control, allowing you to adjust operations as needed for unique circumstances.

This image is property of Amazon.com.

Temperature Control: The Secret to No Leaks

Precision is key when it comes to cup sealing, and temperature plays a crucial role. This machine lets you set the temperature accurately, promising quality seals every single time. Operating 24/7, it maintains a high productivity rate of 500-600 cups per hour—an exceptionally promising figure for businesses hoping to reduce bottlenecks in their service.

Dual Mode Flexibility

One handy feature is the “dual mode all-in-one machine” that you can switch manually or automatically as needed. This flexibility is excellent for adapting to fluctuating customer flows without compromising on efficiency or service quality.

This image is property of Amazon.com.

Technical Support and Guidance Available

It’s comforting to know expert guidance is available around the clock. The manufacturer has thoughtfully offered ongoing technical assistance for all your needs. From operating to troubleshooting, there’s a wealth of resources at your disposal to ensure smooth sailing.

Operation and Troubleshooting

In case you’re worried about operation—particularly if you’re introducing new staff regularly—the company provides operation videos. Troubleshooting guidance is also readily available, should you encounter any initial hiccups. It’s reassuring to have such support, akin to a trusted friend with you at every step.

This image is property of Amazon.com.

Special Circumstances and Usage Notice

Understanding that unique conditions can arise, the WantJoin Cup Sealing Machine accommodates them. For optimal function, they provide specific instructions on sealing films depending on the cup type—PP cups need PP films, PET cups require PET films. The machine thoughtfully includes a sensor alignment system to prevent misalignment, ensuring smoother operations.

Additional Considerations

You should note the importance of correct film usage with corresponding cup materials. This seemingly minor detail can significantly affect the quality and reliability of each seal. Take heed of the sticker instructions provided on the machine, as they guide proper adjustments when necessary.

This image is property of Amazon.com.

Final Verdict: A Solid Investment for High Demand Situations

In summary, the WantJoin Cup Sealing Machine demonstrates robust functionality and adaptability—a vital asset for any modern-day beverage business. It’s efficient, user-friendly, and well-supported by the manufacturer, making it an incredible investment for bolstering productivity without escalating labor costs.

The beauty of this machine truly shines in how it marries technology with human needs, adapting seamlessly to the unexpected twists and turns of a bustling shop. So the next time you find your workflow straining under the weight of high demand, remember that a solution like the WantJoin Cup Sealing Machine is out there, ready to lend a helping hand.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.